Touch with display

Not all touches are the same: There are different technologies that turn a touchscreen into one. Resistive and capacitive technology are often used. Both have their advantages and should be adapted to the respective application. We will be happy to advise you on the optimal solution for you.

Resistive touchscreens

Resistive touchscreens react to pressure. If a spot on the screen is pressed, it is detected by a conductive layer and an interaction is triggered. The advantage is that this works when touched with a bare finger, but also with a glove, for example, when used in medical applications. Resistive touchscreens consume little power and are inexpensive to purchase. However, with around 10 to 17 million touches, they only have a medium service life and the slightly elastic, outer polyester surface is susceptible to scratches. Predominantly small and medium screens use this technology.

Capacitive touchscreens

With capacitive touchscreens, it is not pressure but touch that is decisive. Such a touch changes the voltage of the constant electric field applied to a conductive layer above the glass plate. The advantage of capacitive touchscreens is their long life as well as fast touch response time, high resolution (accuracy), high optical clarity and high resistance to dust, water and scratches. Frequent cleaning is therefore also not a problem.

Bespoke touchscreens

Are you looking for a customized touchscreen that meets your desired dimensions? Would you like to determine the technology or the design of the touchscreen yourself? And that already with a quantity starting from 100 pieces? No problem!

Thanks to our own technology hub in Shanghai and a worldwide partner network, we are also able to offer you individual, customer-specific solutions. Our touch solutions are available as customized versions combined with glass, PMMA, PC, membrane switches or front foils. Please ask us!

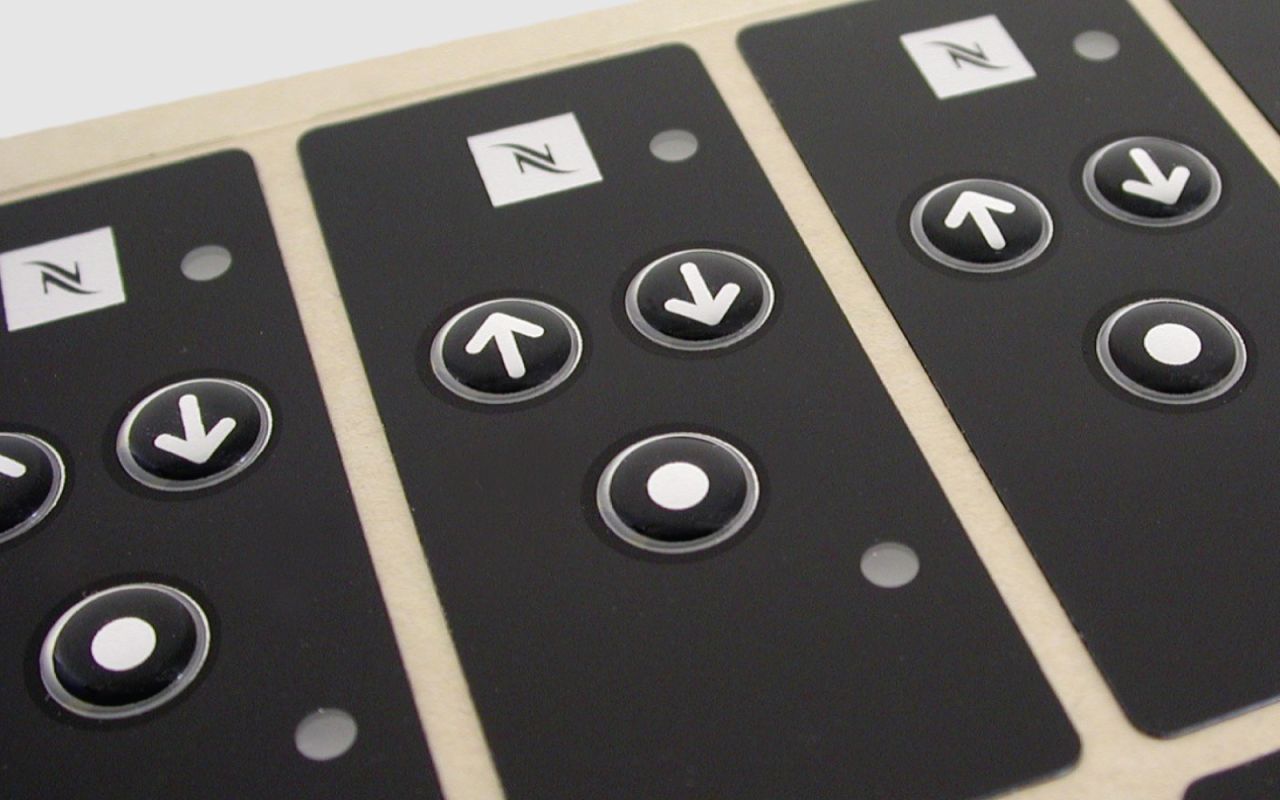

Touch combinations with membrane switch or front foil

We bond the touchscreen to the membrane switch, front foil or safety glass over the entire surface and invisibly in the clean room. The result is a stable unit that can be easily mounted on your device. Further advantages of this unit:

- Combination of touch surface with tactile keys such as on/off or emergency key.

- Integration of capacitive keys outside the touch area possible

- Sealed front

- Protected touch screen

- Foil printed in customized design

- Uniform operator guidance

Optical bonding for maximum sensitivity and transparency

Optical bonding stands for the bonding of layers by means of a liquid, invisible adhesive. In this high-quality process, the air gap between the membrane switch / front foil and the touchscreen is filled. On the one hand, this enables us to achieve direct contact with the sensitive glass. On the other hand, the optimal transparency and brilliance of the graphics is guaranteed and the penetration of dust and moisture is prevented. More details on optical bonding.

The entire assembly from a single source

On request, we also combine the touch unit with displays, PCBs, boards and housings. In this way, you receive the entire assembly ready-mounted and from a single source. All you need to do is install the unit, connect it up - and you're done. As a global system supplier, we also supply you worldwide and take care of the entire logistics for you.

Contact us, we will be happy to advise you personally.

Areas of usage

- Household appliances

- Industrial applications

- Medicine & laboratory technology

- Building technology

- Measurement & Control

- Vehicle construction

- Aviation

- Military