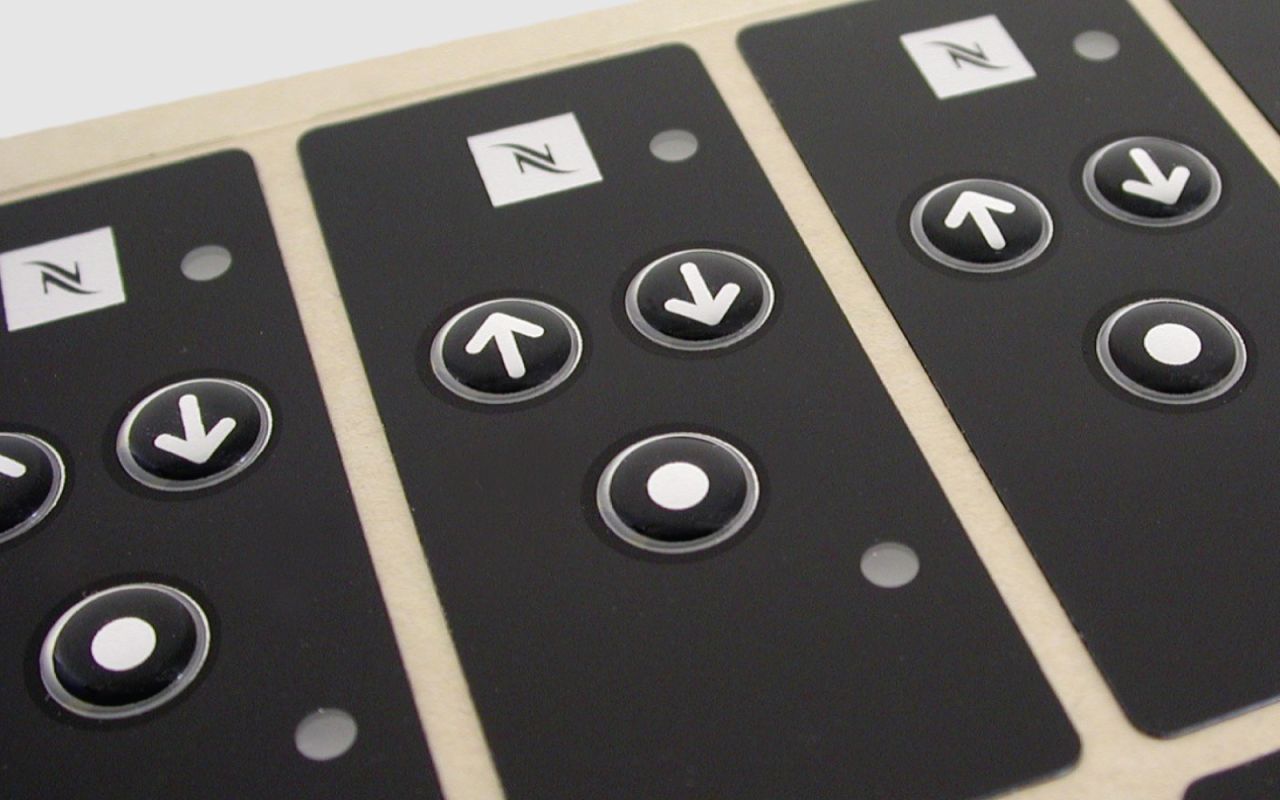

Operating foils, front foils & decorative foils

Operating foils or front foils are printed on the back and thus guarantee maximum protection against moisture, dust and chemicals. In addition, they offer high dimensional stability, good legibility, are scratch-resistant and resistant to heat and cold. In addition, they can be easily bonded to almost any surfaces. Touch elements can be increased by embossing.

Technology

In most cases, the foils consist of four areas:

- the basic material (PET, PC)

- the adhesive

- the printing process used

- mechanical processing if required

If the foil is used to operate buttons, high-quality polyester foils (PET) are used. For pure front foils and decorative foils we apply the proven polycarbonate foils (PC). All foils are available in different thicknesses and surface finishes.

In the printing process, we take into account whether it is a prototype or series production, which design is implemented or which parameters are specified by the customer.

The adhesive is defined according to the surface to be bonded. For this purpose we determine the surface tension of the cover in advance.

The mechanical processing is carried out at customer's request.

Advantages of operating foils, front foils & decorative foils

- customer-specific designs possible

- closed surface, components are protected

- waterproof, dustproof, resistant to mechanical and chemical influences

- very flexible in use

- bonding with display/touch screen possible

- low production costs

- available in small quantities

- short delivery times

- high resistance

- easy assembly

Areas of use

- household appliances

- industrial applications

- medical device manufacturing

Specifics

On request, we can laminate the front foil onto the intended housing or glue the display in a designated clean room.