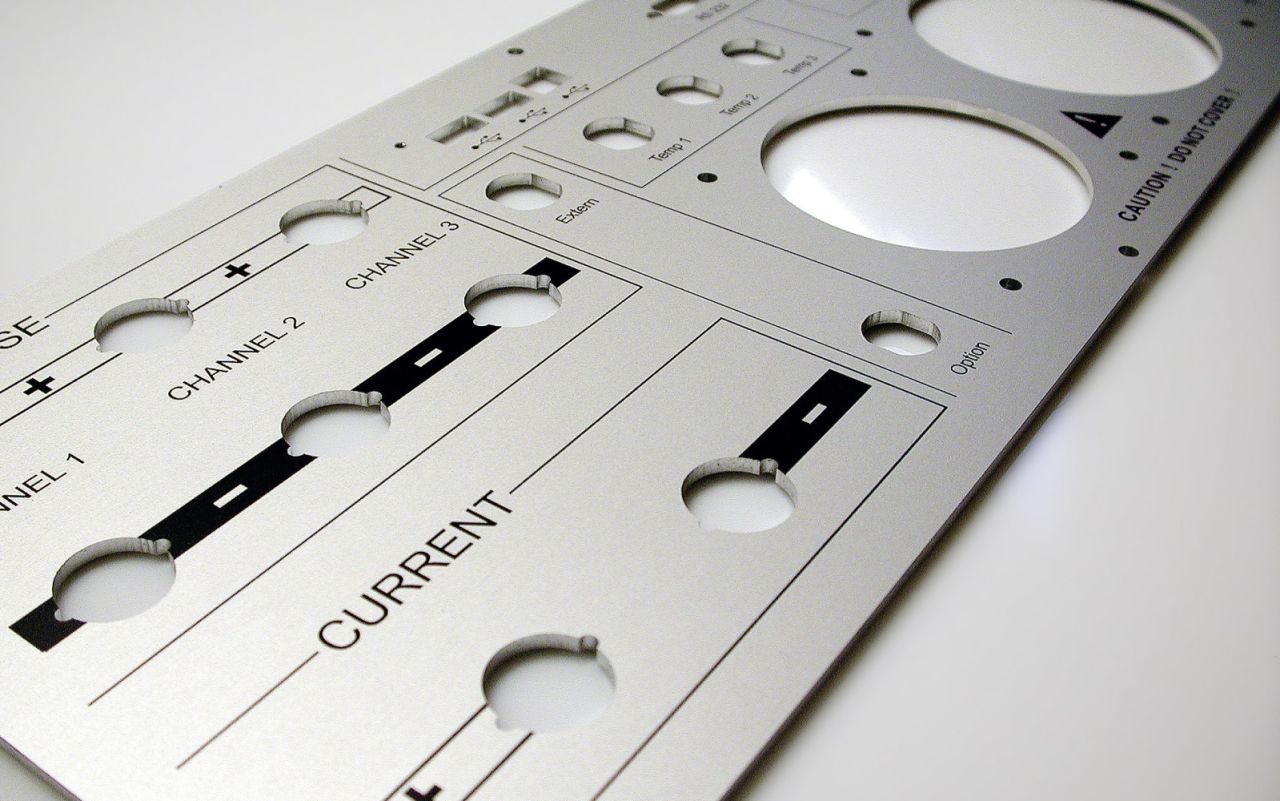

Front panels

Front panels made of plastic or aluminium form a robust front. They are used for elegant labelling of the mechanical switches and displays of your device. We guarantee high precision machining thanks to CNC-controlled machines.

Front panels are as diverse as the devices to which they lend their design. Beyond functionality, they must also convince with visual value.

Front panels from MICHEL ITC meet the most diverse requirements and specifications. There are no limits to shape and design. They can be made of either aluminum or plastic. Openings on the rear side allow the assembly with LCD monitors or short-stroke keys and also an assembly with switches on the front side is possible.

Thanks to the corresponding material thicknesses of the surface and the fastening options, they are the ideal carrier for front foils or membrane switches.

Advantages of front panels

- Wide range of materials: PMMA, PC, aluminium

- Different printing processes for every requirement:

- screen printing

- photorealistic digital printing

- screen printing under eloxal printing

- photorealistic digital under eloxal printing - Individual graphic design of the elements

- Robust, stable front

- Simple assembly